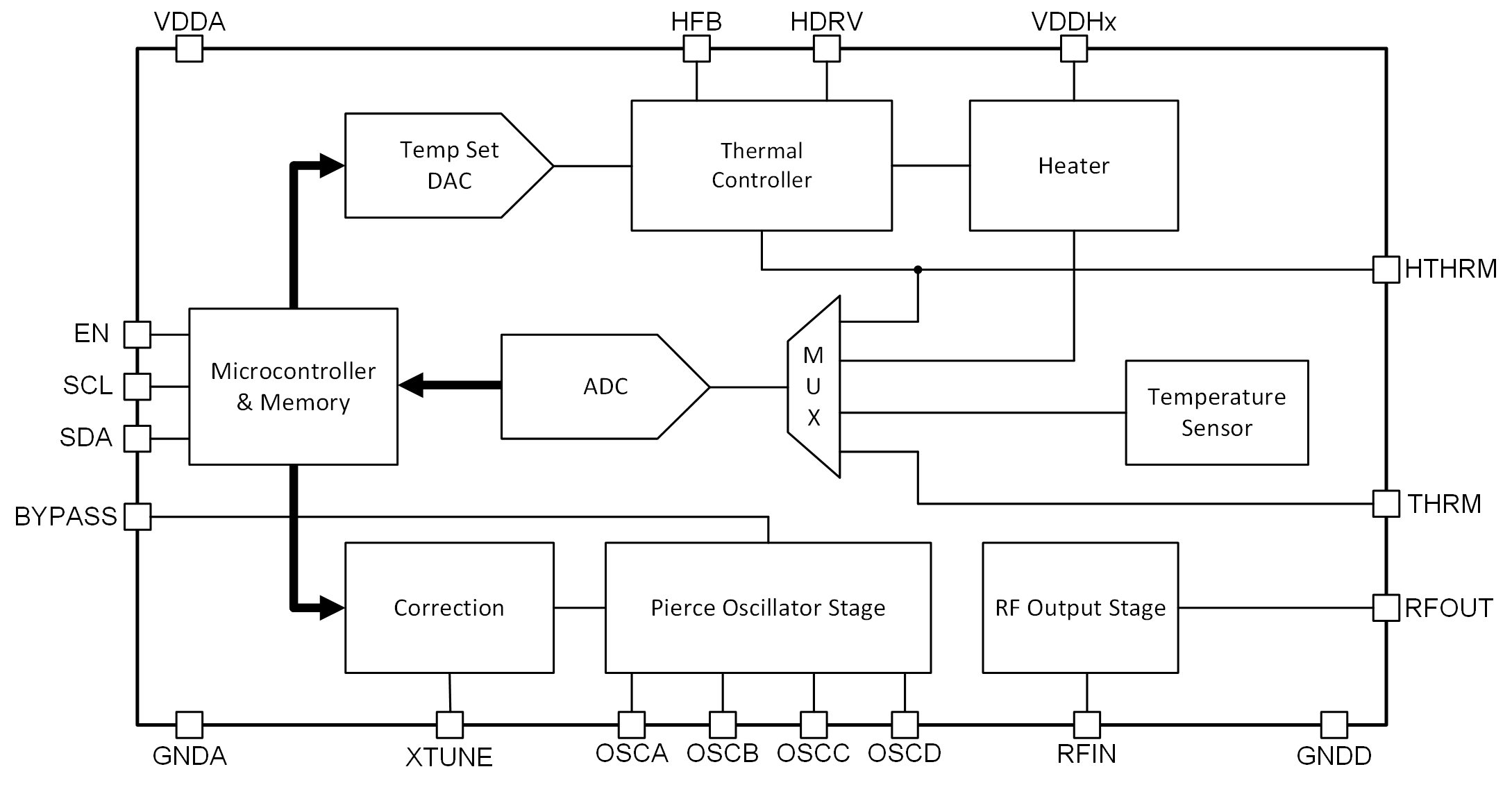

An Oven Controlled Crystal Oscillator (OCXO) is a crystal oscillator that holds the crystal and other oscillator components at one specific temperature while the ambient temperature changes to achieve a very tight frequency stability beyond that of a TCXO (5x-10x better). The components are encapsulated inside an ‘oven’ that operates at a temperature that corresponds with a crystal’s upper turnover point. The turnover temperature must be higher than the upper limit of the ambient temperature range to be able to control the oven. The benefit of holding the crystal at the turnover temperature is that the slope of the frequency versus temperature curve is near zero and small amounts of temperature variation have very little impact on the frequency. For the remaining frequency versus temperature variation, our TM200 uses correction algorithms can be used to further stabilize the output frequency.

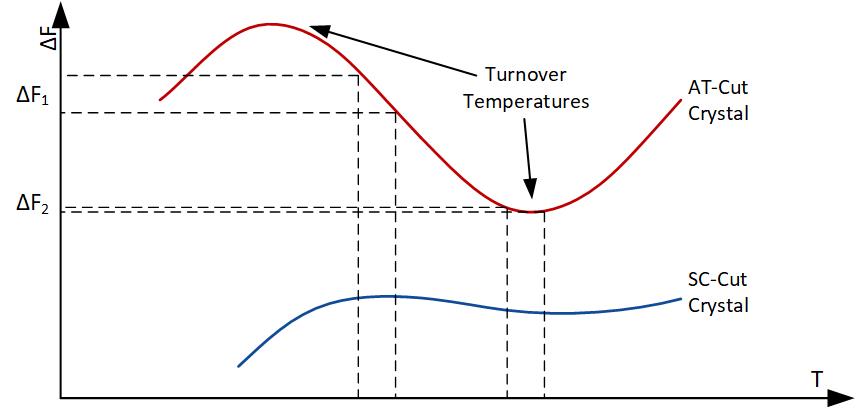

Crystal selection is very important in the design of an OCXO as the turnover point, stability, aging, warm-up time, phase noise, and cost are heavily influenced by the properties of the crystal. AT-Cut and SC-Cut are the most common selections. Commodity OCXOs typically use AT-Cut crystals because of their lower cost and offer good overall performance for many applications by achieving a stability performance of < 50ppb. SC-Cut crystals have a flatter turnover curve which allows them to operate at higher oven temperatures, have higher Q factors and lower G-Sensitivity, but are expensive and harder to work with. Ultimately, crystal selection depends on the OCXO’s application specifications regarding stability, aging, warm-up time, and phase noise performance.

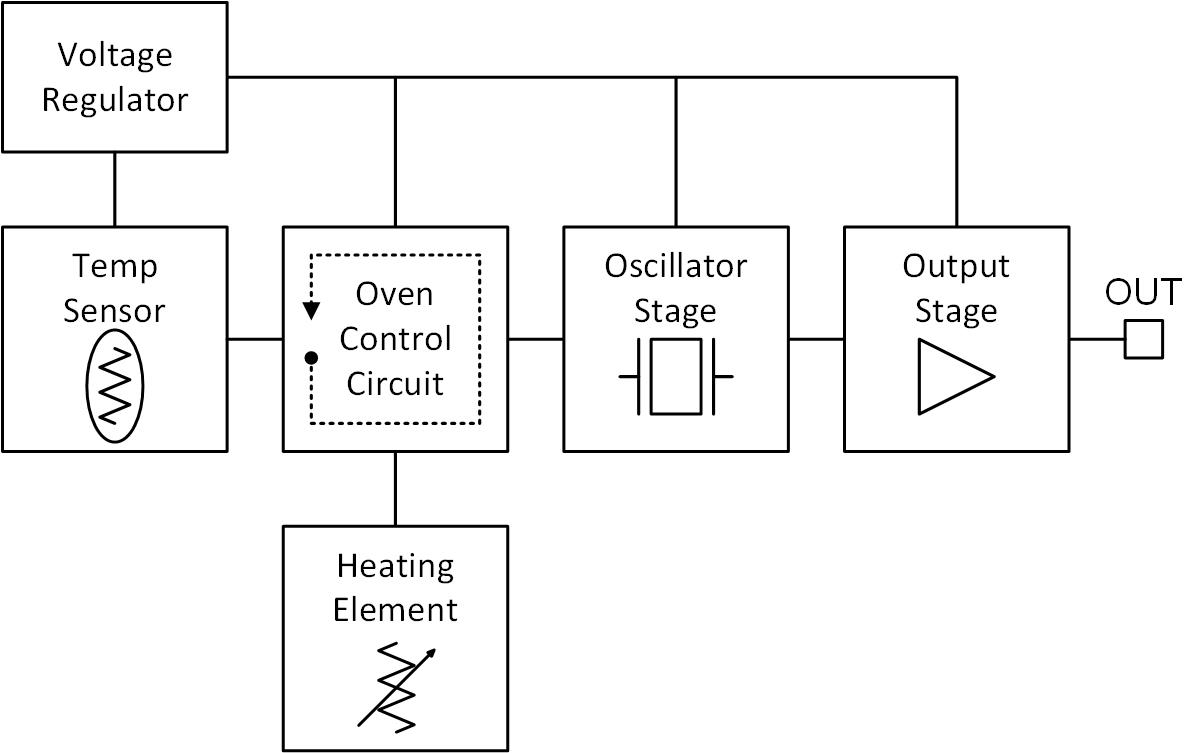

The construction of an OCXO requires a crystal oscillator, temperature sensor (typically a thermistor), heating element, and an oven control circuit that provides the closed-loop feedback to control the thermal characteristics of the oven module. Form factors of OCXO range from 52x52mm down to 5x7mm depending on the stability requirements of the intended application.

The thermal loss from the heating element to the outside environment must be minimized to improve the OCXO thermal control characteristics. Excellent thermal coupling between the temperature sensor and crystal cavity is also essential for tight thermal and frequency control. Specialized circuit architecture and design of the TM200 thermal feedback control loop supports low Allan deviation, especially critical for high stability clocks.

Figure 1

Figure 2

Hexius Products

TM200

Thermal Management IC

-

- Low phase noise oscillator

- < 10 ppb stability with AT-Cut crystals

- Low Allan Deviation for high stability clocks

- High accuracy temperature sensor

- Controls internal (1W) or external heaters

- Embedded microcontroller and memory

- Accepts external thermistor connections

- Simple software configuration

Reference Designs

- Low cost

- <10 ppb stability

- Low phase noise

- AT-Cut Crystal

- 9×7 form factor